By Muthoni Wachira

Competition in the smartphone industry is pretty much alive across the globe. From the flagship/high-end segment to the entry-level segment, how well a manufacturer’s device performs in the hands of the consumers will most likely determine the success of the model and in extension the brand.

One area colossal amounts of money has been invested into is in research and development, where quality tests are conducted.

Quality tests have been designed to reflect the actual consumer experience, so that common but overlooked motions such as USB plug-in and plug-out, and slight drops are not missed. The consumer is now placing more emphasis on high product quality in their choice of smartphones, and the same is reflected in the unrelenting commitment by manufacturers to product quality.

With this background, at OPPO, we adopt stricter testing standards than the industry norms, staying true to our belief in human-centric innovation. Before a particular model goes into mass production, the smartphones are subjected to more than 150 quality engineering tests at the state-of-the-art Quality Engineering (QE) Lab. Throughout the rigorous testing process, we are talking of over 1.1 million actions performed on each phone model.

The QE Lab’s 150 device tests include new material certifications, quality compliance, routine product monitoring, and others, ensuring that each smartphone meets the highest standards of quality and reliability. Quality monitoring continues throughout the product life cycle, from the early development stage to mass production, with sample inspections conducted by the QE Lab.

Taking a deeper look at these actions, the drop test for instance involves raising the device to a height of up to 1.8m and then allowing it to fall freely onto a marble surface from different angles. This checks for failure to function, cracking of the outer shell, and detachments of any components. Since the power and volume keys are most frequently use, the button click test sees each button tapped 100,000 times, and the fingerprint key tapped 1 million times to ensure that the keys are comfortable to touch, functional and intact.

To test the life of the USB and headphone jack, the plugging test has users insert and withdraw the USB frequently to charge the device and play music. In this test, the USB is inserted and withdrawn 10,000 times from different angles or by applying different insertion and withdrawal forces.

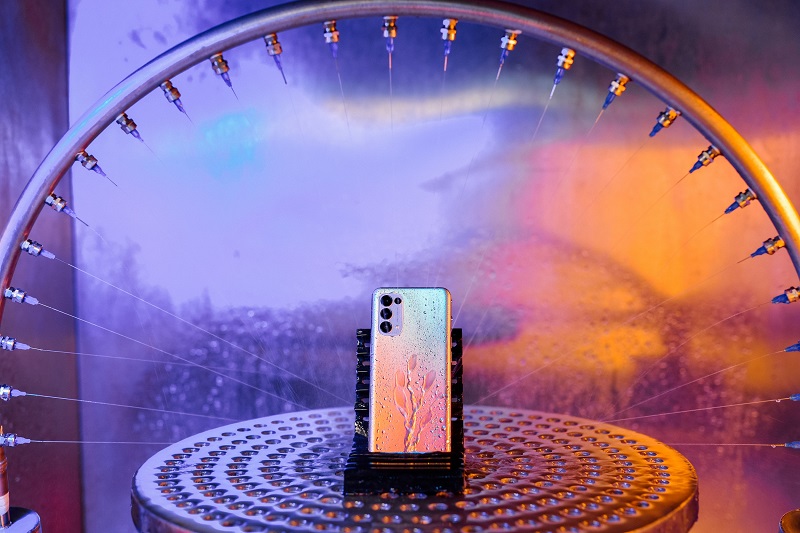

Waterproof performance is now a necessity for the majority of the devices introduced in the market. The OPPO rain test simulates using the device on moderate rainy days. During the test, the device is powered on, while being pitched with water spray from different angles. The device is then set aside for three days to ensure that the water inside the device evaporates and disassembled to verify that the main PCB interface and display screen are not corroded. Additionally, a salt spray test to simulate a coastal area where the air is humid and contains a high proportion of salt aims to verify whether moisture that infiltrates the device corrodes the internal components and other metal parts, causing function failure.

Important to mention also are the press test of the whole device and friction test. The press test simulates a scenario where the user accidentally presses the device against a small, pointed object (such as a key or flash drive in a pocket) and verifies whether the device is damaged, or functionality is affected. The friction test on the other hand uses special sandpaper to rub the case back and forth 2,000 times to test the durability of the phone case.

Overall, OPPO produces more than 85% of products from within our factories to maintain one of the highest industry quality standards. We believe that pushing the boundaries of quality and design, delivering a human-centric experience that surpasses customer expectations will ultimately set apart one industry player from the other.

Wachira is the Head of Communications and Projects at OPPO Kenya